NEW ROLLER COMPACTOR

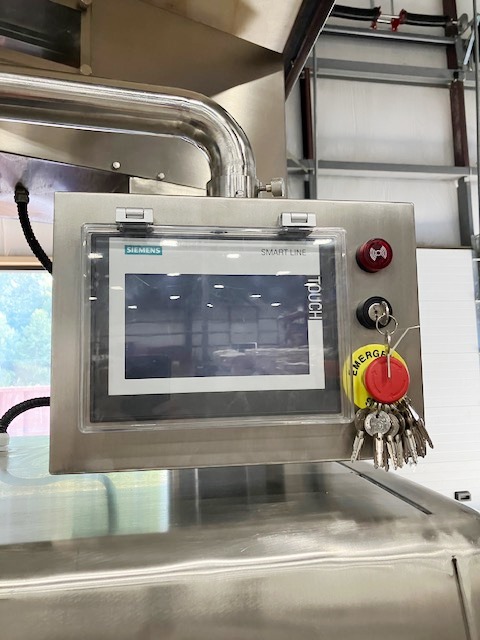

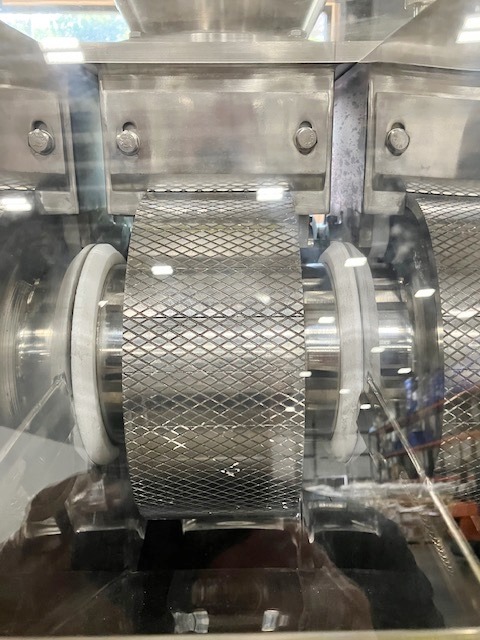

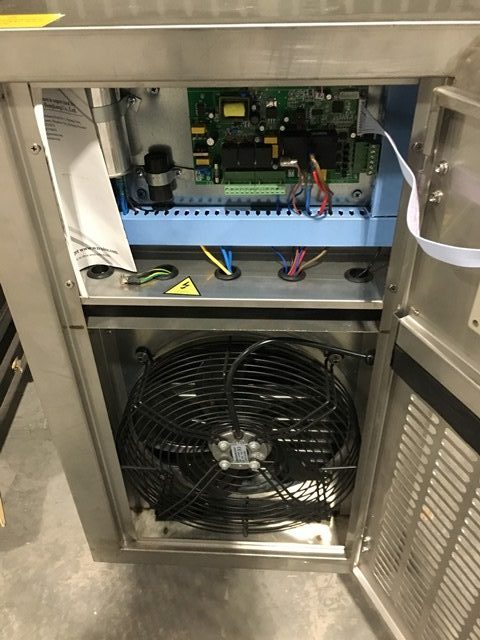

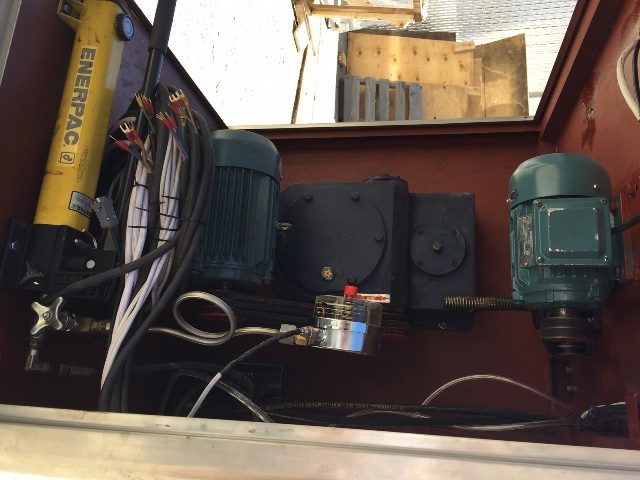

NEW 2023 Roll compactor. Unit is made of stainless steel. Current good manufacturing process. Model RC -100. With roll of 4 x 8. Output: +/- 100 kG per hour, based on ingredient characteristics. Unit contains one main dry compactor and grinding/screening device in enclosed unit. Max. Pressure Hydraulic Thrust is 22 Ton. Total Power is 220 Volt 3 PH 60 Hz. Drive motor: 5.5 KW Frequency Inverter: 5.5 KW. Roller cooling system, utilizes air compressor, high efficiency heat exchanger by inner screw ratio, external rotor motor with low noise and advanced corrosion proof evaporator. Isolated hydraulic seal, internal cooling system with dehumidifier and specially designed roller with pressure control. Overall Size of the unit is Length 1500 x 960 x 2080 MM. Weight of the unit is 1650 KG. After compacting product, product is discharged into a granulator for final processing. The unit comes with a PLC control panel that is mounted on a S/S tube, which is connected to side of machine, so the entire machine can be cleaned without damaging controls. These versatile, heavy-duty roll compactors are built for the most rugged of applications. Designed for dry particle agglomeration, these compacting operations can be set up with a variety of configurations to optimize each process. Roller Size: 208 x 90 mm this compacting machine offers an alternative to agglomeration via wet processing. Instead, high density, free flowing granules are produced directly from the roll compactor. The design employs two-counter rotating rolls force-fed with feed screws. Most materials are processed without the addition of moisture or binders, making our roll compacting systems among the lowest in operating cost.